There are a wide variety of threads available, below I list the seven still currently available from suppliers to classic cars:

| Abbreviation | Name | Standardised in | Angle of Thread | Diameter/ Range | Notes |

| BA | British Association | 1903 | 47.5o Degrees | 16BA to 0BA (0.03 to 0.24 inch) | Mainly electrical |

| BSW | British Standard Whitworth | 1841 | 55o Degrees | 1/16 to 2.5 inches | Coarse |

| BSF | British Standard Fine | - | 55o Degrees | 3/16 to 1 inch | Fine |

| UNC | Unified Coarse Thread | 1918 | 60o Degrees | 0.05 to 1 inch | Coarse |

| UNF | Unified Fine Thread | 1918 | 60o Degrees | 0.05 to 1 inch | Fine |

| ISO Metric Coarse | International Standards Organization Metric Coarse | - | 60o Degrees | 1 to 27mm | Coarse |

| ISO Metric Fine | International Standards Organization Metric Fine | - | 60o Degrees | 3 to 27mm | Fine |

What are they and where do they come from? The fastening systems used in the UK can be divided into three phases:

(1) Up to the Second World War.

(2) After the War until Metrication (c. 1969).

(3) Metrication and afterwards.

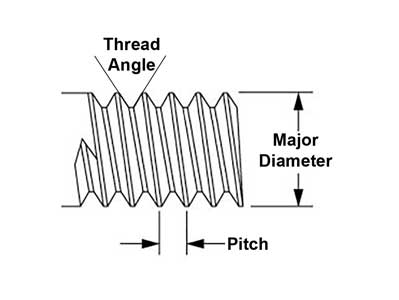

How are they measured? Threads are measured by their diameter, pitch (tpi or threads per inch) and the thread angle:

Until the War, the systems which predominated were Whitworth, BA and BSF.

Whitworth

This was formulated by Sir Joseph Whitworth in 1841 and is very strong due to the radiused corners which reduce the possibility of a stress riser. The thread angles were always 55o.

BA

This is a miniature system founded in 1884 by the British Association (for the advancement of science). Popular sizes are 2BA and the smaller 3BA - the lower the number, the bigger the thread! It is used in electrical equipment and gauges made by Smiths and Jaeger. The thread angle was less than Whitworth at 47½°.

BSF

This is a fine-pitch alternative to British Standard Whitworth (BSW) threads. It was developed by R.E.B. Crompton, CB, FRS in 1908. The thread angle was, as expected, the same as Whitworth at 55o.

After the War, the Allies decided that it would be a good idea to have a common thread system. This is because of difficulties with projects such as Packard in the USA building Rolls Royce Merlin aero engines under licence, when they had to adhere to the Whitworth system to ensure interchangeability with British made engines. As no Whitworth fasteners were available in the US Packard had to make all their own, no mean feat for an engine made up of around 14,000 individual parts.

In November 1948, representatives of the UK, the US and Canada met at the International Organization for Standardization (formed the previous year, in Geneva and popularly known as ISO) and agreed to use the American Standard threads, to be called Unified, hence UNF (Unified National Fine) and UNC (Unified National Coarse). These were widely used in the UK car industry until the advent of metrication in the 1970s. This adaptation was no doubt influenced by our needs to export to the USA. They have a thread angle of 60°.

UNF

This is the ‘fine’ version of the unified threads. It was the most popular thread in cars of the 1950s and 1960s. Specific torque values are often specified.

UNC

This is the coarse version of the above and was used mainly in areas of heat expansion (e.g. exhaust manifolds) as the tolerances are looser.

In 1969 the British government created the Metrication Board as a quango to promote and coordinate metrication. From then on the British motor industry began to replace UNC/UNF threads with metric sizes, which are now used throughout the industry. They maintain the 60o thread angles of the unified system.

Metric Coarse

Metric threads are different because the thread pitch (distance between each thread, in mm) is specified instead of threads per inch or per mm. For example, an M10x1.5 (coarse) thread has a 1.5mm pitch.

Metric Fine

Similarly an M10x1.25 (fine) thread has a 1.25mm pitch.

In the case of Triumph, in the GT6 they maintained the Unified system until the end, but suppliers (e.g. Girling) started using metric threads as in the type 16 caliper which had two versions 16PB (imperial) and 16PB Metric which were used in later versions of the GT6 Mk3 and TR6 from 1972. I believe the later TR7 did use some metric threads in a few areas, but some suppliers (unlike Girling) stuck to the old Whitworth threads, for example S.U. carburettors.