GT6 Suspension

Like all Triumph Herald derivatives (Herald, Vitesse, Spitfire & GT6), the GT6 has fully independent suspension on all four wheels. There are various types of independent suspension systems:

1. Macpherson Strut.

2. Double Wishbone with coil or torsion bar springs.

3. Multi-link.

4. Training arm.

5. Twin i-Beam.

6. Moulton.

7. Transverse leaf spring.

8. Hydropneumatic.

The GT6 has Double Wishbones with coil springs at the front, and a transverse leaf spring at the back.

Front Suspension

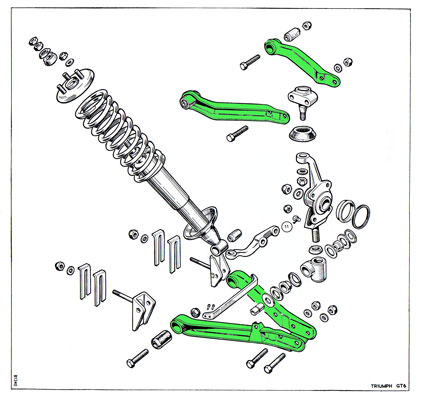

This is by double wishbones and coil springs, where two wishbone shaped arms are connected from the chassis to the front hub assembly, or trunnion. The wishbones arms can be solid, but in the case of the Triumph, the upper arms are split into 2 although each part cannot operate independently of the other (see green highlighted areas in the parts diagram below). The shock absorber is mounted inside the coil spring, both of which are located on the lower wishbone and the chassis.

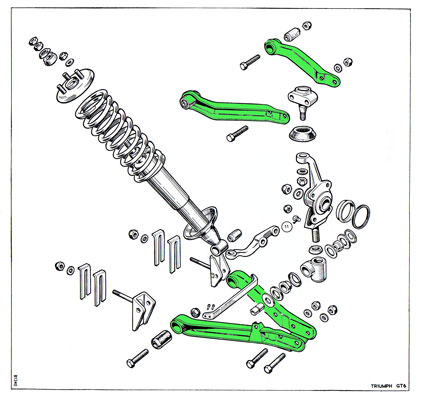

The wishbones can be seen clearly in the photo below (together with their chassis mounting points and bolts):

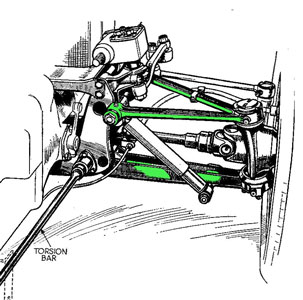

Front suspension by wishbones came out in the 1930s, pioneers including Citroen, Packard (who advertised it as a safetly feature) and Cadillac whose British engineer, Maurice Olley, was a gifted suspension engineer. The revolutionary Citroen Traction Avant of 1934 had front suspension using wishbones and torsion bars (like a spring, but straight) see below:

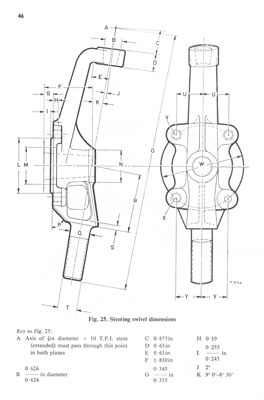

The Standard 8/10 and all TR sports cars all have wishbone front suspension. An interesting feature is the "upright" or Vertical Link, see below (drawing from Olyslager motor manual for the 1956 Standard 8 & 10). This was introduced with the 1938 Standard 8 (yes, the prewar one!) and is also known as the Alford & Alder upright. This Hemel-Hempstead based company (which was ultimately absorbed into Standard-Triumph) designed and manufactured this upright which is famous for its use in many racing cars including three world championship winners - the 1959 and 1960 Coopers and the Brabham-Repco BT20 of 1966. It is still used to this day in the Caterham Seven. For more information look at my 'Articles' page or click here.

Recently I came across an article in Classic & Sportscar about the late 1960s Maserati Ghibli. This was described as having Alford & Alder front suspension, so these vertical links were even used in some Italian exotica!

Rear Suspension

The rear suspension uses a transverse leaf spring and swing axle, inherited from the Triumph Herald. Transverse rear leaf springs and swing axles were not uncommon, having been used prewar in the Alfa Romeo Tipo C, and postwar in the Chevrolet Corvair.

Sometimes referred to as 'semi-elliptical' or 'cart springs', a typical leaf spring is made up of a cross-section of rectangular cut spring steel 'leaves' which are bent and fixed together to form an arc shape. The majority of leaf springs have a longest leaf or 'main leaf' where the ends are heated and rolled to form circular shapes called 'eyes'. These eyes allow the spring to connect to the vehicle body while the centre of the spring allows location to the axle. Normally below the main leaf are a number of leaves which are usually progressively shorter, however in the case of the small chassis Triumphs, the shortest leaf is at the top. A leaf spring can be made up of a single leaf or over 20 leaves depending on the application.

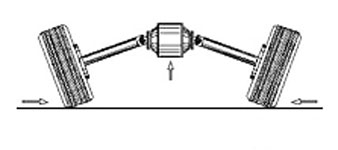

Swing axles are a British invention, by an Edmund Rumpler in 1903. Their principal advantages are each wheel is independently sprung, and a reduction in unsprung weight since the differential is mounted to the chassis (i.e. is no longer part of the suspension). Their most recent use includes Volkswagens up to 1967, the Mercedes 300SL, Porsche 356, Tatras, Chevrolet Corvair, as well as the Triumphs. The principal drawback to this type of suspension is well known : that there is an extreme amount of camber change from bump to droop and that this can cause "jacking" under extreme cornering (see below)

As can be seen the tyre contact area becomes minimal with a consequent loss of grip (it happened to me many years ago in my Triumph Herald

Coupé which 'spun'. Fortunately for me at the time there was no other traffic or I may well have hit something!). Many engineering solutions have been devised to

solve this problem. Triumph came up with two:

1. The The "swing spring" pivoted the transverse rear spring on the differential, so that the body could roll more than the suspension, without impairing the ride in a straight line.

This solution was considered very early by Standard-Triumph engineers, but

rejected for various reasons, one of which was that they didn't think it was

really necessary! When they were criticised by the motoring press for the

handling, particularly of the GT6 Mk1, they came up with the 'Rotoflex'

suspension introduced in the GT6 Mk2, but not fitted to the Spitfire on cost

grounds. Ironically the 'swing spring' was resurrected for the Spitfire MklV and

late Mk3 GT6s as although not quite as effective as the 'Rotoflex', it was much

cheaper.

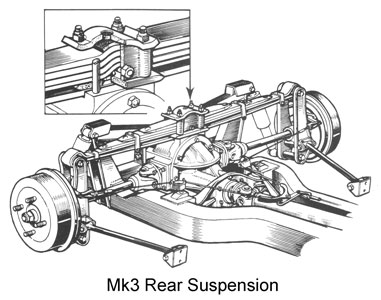

2. A fully controlled rear axle, with a lower wishbone (reversed) and a rubber coupling or doughnut (Rotoflex) at the outer end of the drive shaft, but that was no longer a swing axle.

The 'Swing Spring' is used in the later GT6 Mk3 as well as the Spitfire Mk4/1500. 2. The 'Rotoflex' is used in the Mk2 and early Mk3 GT6. Please refer to the Rotoflex section of this website for details of this rubber coupling.

Transverse rear springs used as top locators for the rear hub, along with lower wishbones (GT6 Mk2 and early Mk3) were used in the 1957 Cooper T43 Formula 2 Racecar which was designed by Richard Maddock. The rear suspension can be seen below, the similarity to the GT6 is marked, with the upper transverse spring located on the transaxle (axle in the case of the GT6) and a lower wishbone (tubular steel in the case of the Cooper, cast aluminium in the GT6).

![]()