Carburation

A carburettor is a device that mixes air and fuel for internal combustion engines in the proper ratio for combustion, more recently carburettors in modern vehicles have been replaced by fuel injection. In the late 1950s the carburettor of choice for British sporting cars was the SU, a constant vacuum (or depression) device invented by Herbert Skinner in 1904 (SU = Skinner Union). SU were sold to Morris Motors in 1918 (later incorporated into the British Motor Corporation). However around 1958/59 BMC announced that it could only supply SU carburettors to motor manufacturers outside BMC itself if there was enough manufacturing capacity to do so. This left Standard Triumph with a problem. They had tried the Solex carburettor in the then new Vanguard 6, but it was not entirely successful. An alternative constant vacuum carburettor had to be developed which didn't infringe on SU patents. Thus the Stromberg was born.

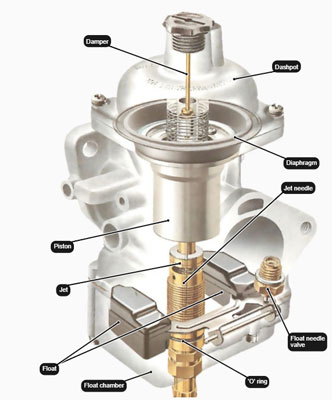

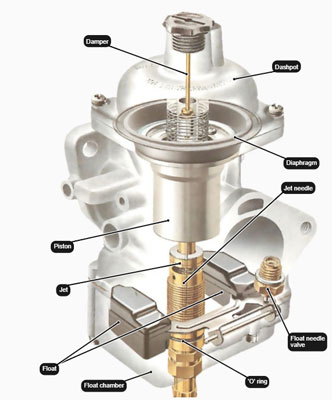

All GT6s are fitted with twin Stromberg CD150 carburettors. The Stromberg CD is a constant vacuum carburettor (CD means Constant Depression). They work in a similar way to the SU, but the Stromberg differs in having the air valve or piston surrounded by a rubber diaphragm in the dashpot. The size and type of a Stromberg are given by numbers and letters. Numbers such as 125, 150 and 175 are mean a choke diameter of 1 1/4, 1 1/2 and 1 3/4 in. Types include CD, CDS, CD2S and CD3.

Standard-Triumph subsidiary Alford & Alder (mainly known for making rack and pinion steering assemblies and suspension parts) had a bright young engineer called Dennis Barbet. Starting with a clean sheet he designed an ingenious rubber diaphragm to control the air/fuel supply. According to Paul Richardson "the diaphragm still relied on throttle controlled vacuum on its upper surface to meter fuel via the jet and needle, but did away with the metal piston/cylinder arrangement of the SU." Paul asked Dennis how he came up with the idea. "Well the new carburettor had to work on the constant vacuum principle, but I had to find another way to control the air/fuel mixture via the variable choke. I suppose the idea of using the rubber diaphragm was due to the fact that I'd designed several pneumatic clamping devices involving rubber seals and diaphragms. The thought ran through my mind that if a rubber diaphragm could be clamped at its periphery to the carburettor body and to the movable choke assembly at its centre, I'd still have a constant vacuum carburettor, but a new way of controlling the needle in relation to the fuel jet orifice". The first application of this carburettor was the 948cc Triumph Herald.

At the time Alford & Alder were not interested in producing carburettors which differed from their core products of steering and suspension components. Standard-Triumph arranged for the Zenith Carburetter Company, a British company making carburettors in Stanmore, Middlesex to make the Stromberg CD carburettors for them.

According to Wikipedia:-

Designed and developed by Denis Barbet (Standard Triumph) and Harry Cartwright (Zenith) in order to break SU's patents, the Stromberg carburettor features a variable venturi controlled by a piston. This piston has a long, tapered, conical metering rod (usually referred to as a "needle") that fits inside an orifice ("jet") which admits fuel into the airstream passing through the carburettor. Since the needle is tapered, as it rises and falls it opens and closes the opening in the jet, regulating the passage of fuel, so the movement of the piston controls the amount of fuel delivered, depending on engine demand.

The flow of air through the venturi creates a reduced static pressure in the venturi. This pressure drop is communicated to the upper side of the piston via an air passage. The underside of the piston is in communication with atmospheric pressure. The difference in pressure between the two sides of the piston creates a force tending to lift the piston. Counteracting this force is the weight of the piston and the force of a compression spring which is compressed by the piston rising; because the spring is operating over a very small part of its possible range of extension, the spring force approximates to a constant force. Under steady state conditions the upwards and downwards forces on the piston are equal and opposite, and the piston does not move.

If the airflow into the engine is increased - by opening the throttle plate, or by allowing the engine revolutions to rise with the throttle plate at a constant setting - the pressure drop in the venturi increases, the pressure above the piston falls, and the piston is sucked upwards, increasing the size of the venturi, until the pressure drop in the venturi returns to its nominal level. Similarly if the airflow into the engine is reduced, the piston will fall. The result is that the pressure drop in the venturi remains the same regardless of the speed of the airflow - hence the name "constant depression" for carburettors operating on this principle - but the piston rises and falls according to the speed of the airflow.

Since the position of the piston controls the position of the needle in the jet, and thus the open area of the jet, while the depression in the venturi sucking fuel out of the jet remains constant, the rate of fuel delivery is always a definite function of the rate of air delivery. The precise nature of the function is determined by the tapered profile of the needle. With appropriate selection of the needle, the fuel delivery can be matched much more closely to the demands of the engine than is possible with the more common fixed-venturi carburettor, an inherently inaccurate device whose design must incorporate many complex fudges to obtain usable accuracy of fuelling. The well-controlled conditions under which the jet is operating also make it possible to obtain good and consistent atomisation of the fuel under all operating conditions.

This self-adjusting nature makes the selection of the maximum venturi diameter (colloquially, but inaccurately, referred to as "choke size") much less critical than with a fixed-venturi carburettor.

To prevent erratic and sudden movements of the piston it is damped by light oil in a dashpot (under the white plastic cover in the picture) which requires periodic topping up.

One of the major drawbacks of the constant depression carburettor is in high performance applications. Since it relies on restricting air flow in order to produce enrichment during acceleration, the throttle response lacks punch. By contrast, the fixed choke design adds extra fuel under these conditions using its accelerator pump.

To find out how to overhaul a Stromberg carburettor click here.

![]()